- Automotive manufacturers face increasing pressure to manage waste sustainably and comply with complex regulations.

- Nextbitt’s Waste Management module streamlines supplier reporting and validation, reducing administrative effort and risk.

- Integration with asset and facility management systems creates full operational visibility and efficiency.

Problem Context

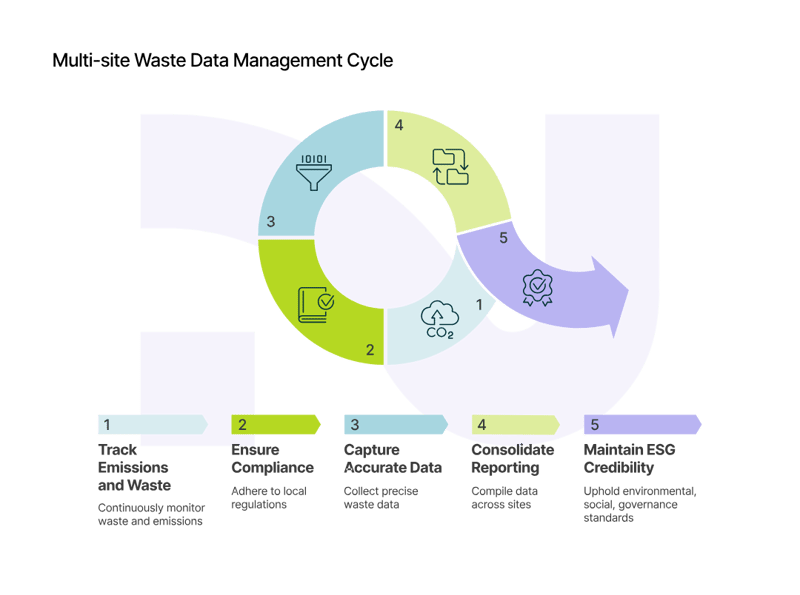

In the automotive industry, sustainability is no longer a CSR (Corporate Social Responsibility) box to check — it’s an operational mandate. As global supply chains tighten their environmental reporting requirements, manufacturers must keep track not only of their emissions and energy usage, but also their solid and hazardous waste output.

For multi-site manufacturers with outsourced waste collection, keeping up with local legislation, ensuring accurate data capture, and consolidating reporting across regions has become a major operational burden. A small inconsistency in reported waste volumes can trigger fines or compliance audits. Worse, it undermines ESG credibility.

Technical Diagnosis

The main issue is fragmented data ownership. Waste is managed by third-party providers, but regulatory responsibility stays with the manufacturer. Suppliers report in inconsistent formats, and internal teams are forced to normalise and validate data manually — often with little transparency.

“You don’t manage what you don’t see. Waste data is still the blind spot in most sustainability dashboards.”

— Duarte Almeida, Consulting Lead at Nextbitt

Solutions and Trade-offs

To address this, manufacturers typically face three options:

|

Solution |

Complexity |

Automation Level |

Risks |

|

Manual spreadsheets + audits |

Low |

None |

High error rate, slow response |

|

In-house custom development |

High |

Medium |

Long time-to-value, high cost |

|

Integrated waste management tool |

Medium |

High |

Needs supplier onboarding |

Nextbitt’s Waste Management solution offers a clear edge:

- Suppliers submit data directly to the platform

- Automatic validation flags inconsistencies

- Facilities teams only need to approve exceptions

Real-World Use Case

Automotive manufacturers around the world are proving that waste management is not just about compliance — it’s a driver of operational excellence and sustainability. Here are three industry-leading examples that show what’s possible:

Subaru of Indiana Automotive (SIA)

Subaru of Indiana Automotive became the first U.S. auto assembly plant to achieve GreenCircle’s Zero Waste to Landfill certification in 2023. The facility implemented a series of waste-reduction strategies, such as reusable packaging for incoming parts, colour-coded waste containers to reduce contamination, and rigorous supplier engagement. These initiatives enabled SIA to recycle, reuse, or recover 100% of its operational waste.

Impact:

- Certified as zero waste to landfill by Green Circle in 2023

- Achieved a 95% reduction in waste per vehicle since 2004

- Eliminated over 2,000 tonnes/year of landfill waste through packaging redesign and process improvements

🔗 Modern Casting – From Dumpster Dive to Certified

🔗 GreenCircle Certified – Subaru of Indiana Automotive

General Motors - Flint Engine Operations

General Motors’ Flint Engine Operations in Michigan was the company’s first site to reach landfill-free status, back in 2005. This milestone was achieved through practices like recycling metal chips from the machining process and redirecting non-recyclable material to waste-to-energy systems. Since then, GM has expanded the initiative across its global network.

Impact:

- All GM manufacturing facilities in Canada, Mexico, and South America reached landfill-free status by 2018

- A total of 142 landfill-free facilities globally

- Flint remains a benchmark for integrating circular economy principles into day-to-day automotive operations

🔗 General Motors – Expands Landfill-Free Efforts Globally

Honda Marysville Auto Plant

Honda's Marysville Auto Plant in Ohio has been a pioneer in waste reduction, achieving significant milestones in its sustainability journey. In 2009, the plant initiated a program to reduce metal scrap by optimizing the size of steel sheets used in stamping body parts. This initiative not only minimized waste but also reduced the environmental impact associated with transporting and recycling steel. The success of this program led to its adoption in other Honda facilities across North America. Additionally, the plant has implemented various waste-reduction and recycling activities, contributing to Honda's broader goal of achieving zero waste to landfill in its manufacturing operations.

Impact:

- Implemented innovative stamping processes to reduce steel scrap

- Adopted waste-reduction initiatives that have been replicated across other Honda plants

- Contributed to Honda's achievement of zero waste to landfill in multiple North American manufacturing facilities

🔗 Honda In America – Zero Waste Initiatives

“These results aren’t exclusive to the largest players. With the right digital tools, mid-sized automotive manufacturers can achieve full visibility, regulatory compliance, and scalable sustainability across waste operations.”

— Duarte Almeida, Consulting Lead at Nextbitt

Nextbitt’s Waste Management module is designed to deliver this — combining supplier reporting automation, anomaly detection, and audit-ready dashboards in a modular platform built for real-world operations.

Stats and Benchmarks

- According to a recent McKinsey report, digital automation in manufacturing environments can increase productivity by up to 30%, particularly when combining human operations with machine data in real-time decision-making contexts.

🔗 McKinsey & Company, 2022

- 62% of global automotive companies now have a defined sustainability strategy, but many still struggle with the digitalisation of waste management, one of the most under-optimised operational areas.

🔗 Capgemini Research Institute, 2020

- According to the European Environment Agency, industrial waste generation in the EU is rising, with increasing regulatory pressure on high-output sectors such as automotive. Enforcement of compliance has intensified across member states in the last decade.

🔗 European Environment Agency (EEA), 2023

Technical Evaluation Checklist

- Compliance: Fully compliant with EU waste directive formats

- Supplier Access: supports supplier logins and reporting automation

- Scalability: scales to multi-site operations

- Data validation: cross-validates with facility occupancy data

- Integration: integrates with EAM and Energy modules

Product Integration and Use

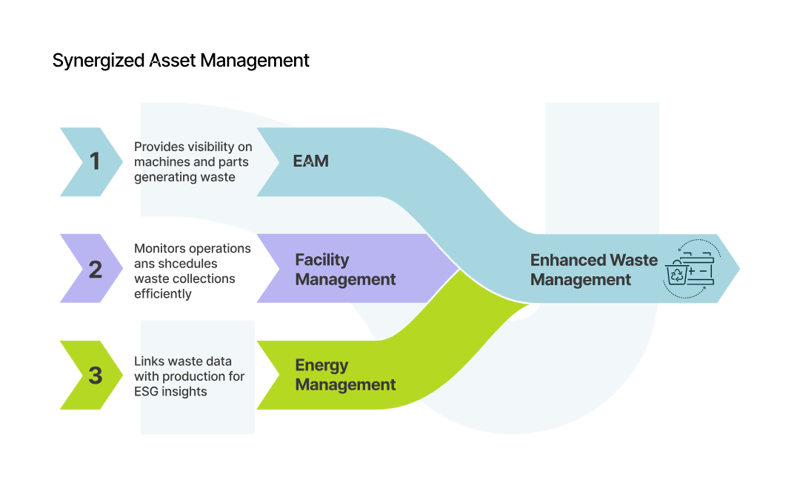

Nextbitt’s Waste Management module is part of an integrated suite that supports:

- Enterprise Asset Management (EAM) – Visibility over machines and components that generate waste

- Facility Management – Scheduling and monitoring waste services across buildings

- Energy Management – Correlating energy use with waste output for better ESG insights

Want to see how automated waste reporting works in your company?

[Request a demo]

Final Thoughts

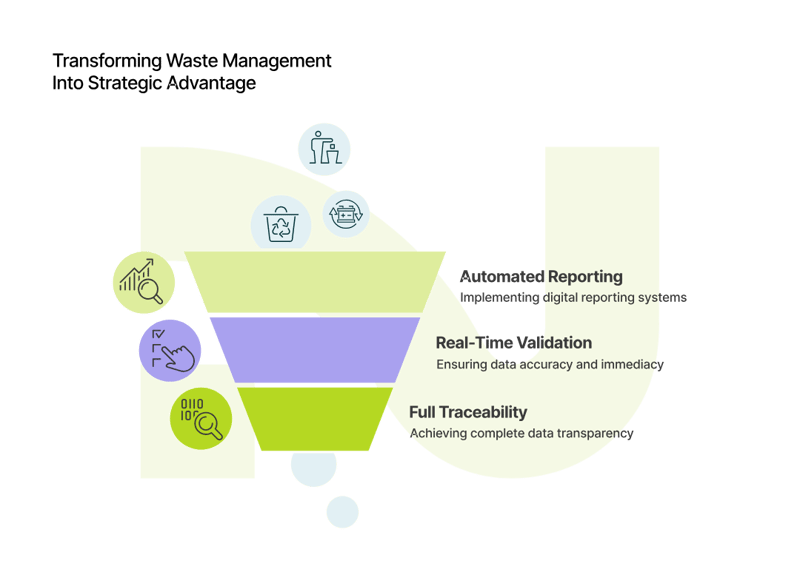

The automotive industry is under increasing pressure to meet sustainability targets while ensuring operational resilience. Waste management — once treated as a peripheral concern — is now central to ESG credibility, regulatory compliance, and operational efficiency.

With automated supplier reporting, real-time validation, and full traceability, Nextbitt’s Waste Management module helps manufacturers transform a compliance burden into a strategic advantage.

As McKinsey has shown, combining human operations with digital automation can unlock up to 30% productivity gains in manufacturing. When paired with integrated waste tracking, this shift doesn’t just save time—it helps reshape how sustainability is measured and achieved.

And with 62% of the global automotive sector already aligning digital tools to their environmental roadmaps, now is the time to act.

Technical FAQ

- Can this solution handle hazardous waste reporting?

Yes. The module supports specific data formats for hazardous waste and integrates with national registries where applicable. - What’s needed to onboard suppliers?

Suppliers receive credentials and submit data via a secure portal or API. Nextbitt provides onboarding support. - Can I integrate this with my existing CMMS or ERP?

Yes. The platform supports API-based integrations with standard ERP, CMMS, and BI tools.

.png?width=50&height=50&name=baixados%20(1).png)