Food manufacturers face growing compliance and operational efficiency pressures, often hampered by fragmented asset tracking and manual reporting.

- IoT-driven predictive Enterprise Asset Management (EAM) extends asset life, drives compliance with HACCP and ISO standards, and prevents costly recalls.

- Nextbitt centralizes asset information, automates preventive and predictive maintenance, enforces SLAs, and delivers real-time, audit-ready dashboards for multi-site operations.

Problem Context

The food and beverage industry operates under intense regulatory scrutiny and market demands for food safety, transparency, and cost control. The World Health Organization estimates 1.6 million people fall ill daily from unsafe food worldwide, leading to estimated economic losses exceeding $110 billion annually, predominantly in developing regions WHO, 2025.

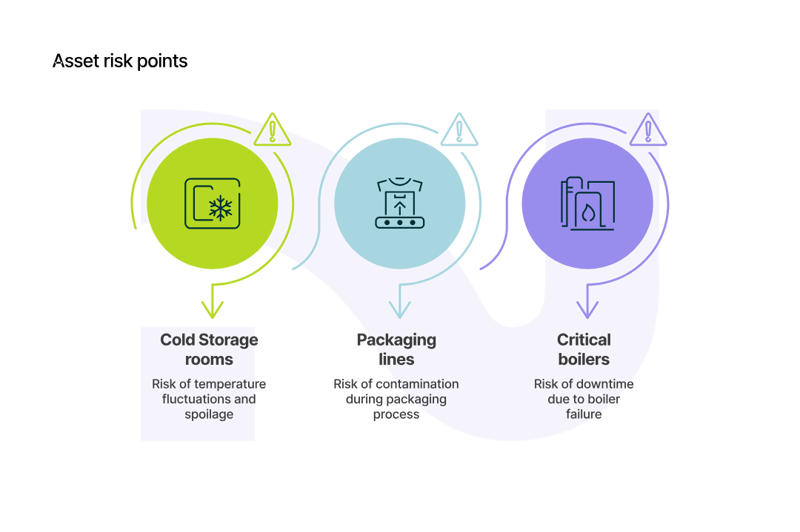

Food manufacturers must maintain highly reliable equipment such as industrial refrigeration, conveyors, boilers, and packaging machinery, all critical in avoiding contamination, spoilage, or downtime. Compliance frameworks like HACCP, ISO 22000, FDA and EFSA requirements stipulate rigorous asset recording, monitoring, and audit trails.

Despite these pressures, many facilities still rely on manual data entry, paper-based HACCP logs, and isolated CMMS systems. This creates fragmented information silos, complicates traceability, and increases the probability of costly audit failures or product recalls.

Industry Trends Shaping Food Manufacturing

Digital Transformation and AI

According to the 2025 State of Food Manufacturing Digital Transformation report, companies investing 26–50% of budgets into automation and AI technologies like real-time monitoring, robotics, and digital asset management are realizing the highest ROI and operational resilience.

Learn more at Food Industry Executive 2025 Report.

Sustainability and Transparency

Consumer demand for transparency and sustainable practices is reshaping supply chains. Real-time tracking of raw materials, waste reduction initiatives, and sustainable packaging innovations are essential focus areas for differentiation and compliance with evolving regulations.

Read details at AZTI - 10 Key Trends Reshaping Food Industry in 2025.

Biotech and Novel Proteins

Emerging technologies like precision fermentation, alternative proteins, and bio-based packaging are redefining product portfolios. This accelerates the need for flexible and digitally integrated manufacturing assets to support varied process requirements at scale.

Explore more at EIT Food – Top Food Trends 2025.

Technical Diagnosis

Manufacturers face recurring challenges:

- Cold Chain Monitoring Gaps: Inadequate integration of IoT sensors leads to late detection of critical temperature disruptions.

- Paper-Based HACCP Records: Slow consolidation and poor traceability cause audit rework and compliance risks.

- Predominantly Time-Based Maintenance: Reactive approaches lead to higher downtime and costs.

- Fragmented Data Silos: Quality, procurement, and maintenance systems operate independently, impeding integrated decision-making.

Food Navigator 2025 insight:

“North America’s food recalls cost $1.9 billion in 2024, with labeling errors responsible for nearly half of incidents.” Food Navigator

Solutions and Trade-offs

|

Solution |

Food Safety Assurance |

Maintenance Type |

Audit Readiness |

Data Visibility |

|

Paper + Excel |

Low |

Reactive |

Poor |

Minimal |

|

Legacy CMMS |

Medium |

Time-based |

Limited |

Medium |

|

Nextbitt EAM + IoT |

High |

Predictive / Condition-based |

Audit-ready |

Real-time |

Nextbitt offers:

- Unified digital asset register with seamless IoT integration for cold chains, packaging, and critical equipment.

- Automated preventive maintenance linked to HACCP-driven compliance workflows.

- SLA enforcement for vendor activities, with real-time operational dashboards.

- Audit-ready electronic logs satisfying ISO 22000, HACCP, and EFSA/FDA standards.

Real world use case

Multinational Dairy Producer

- Real-time IoT monitoring deployed to over 400 cold rooms.

- Product spoilage reduced by 30% due to early anomaly detection alerting.

- Audit preparation time cut from 21 days to 3 days.

- Preventive maintenance cycles fully integrated with ERP CAPEX planning.

Industry comparables include:

- US food recalls costing $1.92 billion in 2024, average recall costing $10 million New Food Magazine.

- Predictive maintenance reduces downtime by up to 50% and extends asset life by 20–40% McKinsey, 2021.

ROI and Sustainability Benefits of Digital Asset Management

- Reduced Downtime and Waste: Predictive alerts minimize spoilage and equipment failure, improving OEE and yield.

- Audit Efficiency Gains: Digital HACCP and regulatory reporting reduce audit prep time by up to 80%, saving staff hours and costs.

- Energy and Resource Savings: Integrated operational data enables targeting inefficiencies, reducing energy consumption and carbon footprint.

- Supply Chain Transparency: Traceability improvements support sustainability certifications and consumer trust initiatives.

The combination of operational, regulatory, and sustainability benefits increasingly guides capital approval decisions for digital transformation investments.

Technical Evaluation Checklist

- Predictive maintenance for refrigeration, conveyors, and packaging systems.

- HACCP audit-ready digital workflows and inspection management.

- IoT sensors for real-time environmental and asset condition monitoring.

- SLA automation for internal & external vendor management.

- Mobile field apps for frontline operators.

- ERP, procurement, and quality system integrations.

- Regulatory compliance logging for HACCP, ISO 22000, FDA/EFSA.

Stats and Benchmarks

- 1.6 million people fall ill daily from unsafe food globally, costing over $110 billion annually in LMICs WHO, 2025.

- US food recalls cost $1.92 billion in 2024; labeling errors drive 45% of recalls New Food Magazine, 2025.

- Average direct recall cost: $10 million, excluding reputational and legal impacts GoVisually 2024.

- McKinsey & Co. (2021): Predictive maintenance cuts downtime by 50%, reduces maintenance costs by 25%, and extends asset life by 20-40% through AI and IoT McKinsey.

- Food and beverage market predicted to grow from $7.4 trillion in 2025 to $9.42 trillion in 2029 StartUs Insights, 2025.

Product Integration and Use with Nextbitt

Nextbitt empowers food manufacturers to:

- Digitize asset inventories comprehensively (cold rooms, boilers, conveyors, packaging).

- Deploy IoT sensor networks to monitor real-time temperature, humidity, pressure, and energy use.

- Automate maintenance workflows aligned with HACCP and audit requirements.

- Seamlessly integrate asset and compliance data into enterprise ERP and procurement systems.

- Provide leadership with dashboards enabling data-driven CAPEX and compliance strategies.

Final Thoughts

Food manufacturing demands more than efficiency. It requires trust through transparent, reliable, and auditable processes. Failures in asset and maintenance management risk costly recalls, downtime, and loss of customer confidence. Nextbitt bridges technology and compliance with IoT-enabled predictive EAM, empowering safer, leaner, and compliant food production.

Technical FAQ

-

Does Nextbitt support HACCP and regulatory processes?

Yes, with fully digital HACCP logs, automated preventive inspections, and audit-ready reporting, including ISO 22000 and FSMA compliance. -

How does IoT integration help cold chains?

Real-time environmental monitoring triggers instant alerts for threshold breaches, minimizing product spoilage and regulatory non-compliance. -

Is Nextbitt scalable for multi-site global operations?

Absolutely. Corporate dashboards aggregate asset health, compliance metrics, and CAPEX planning across global facilities. -

What ROI can I expect?

Typical ROI includes 30–50% downtime reduction, 60–80% faster audit readiness, and enhanced CAPEX decision-making.

.png?width=50&height=50&name=baixados%20(1).png)