Aviation ground handling and support operations depend on highly reliable equipment, infrastructure, and logistics processes. Any downtime directly impacts airline schedules and passenger experience.

Nextbitt’s platform enables aviation operators to centralise asset management, automate maintenance workflows, optimise inventory, and gain real-time visibility over performance and compliance.

One aviation operator now manages over 5,300 assets across six major airports with Nextbitt — improving reliability, SLA performance, and resource allocation.

Problem Context

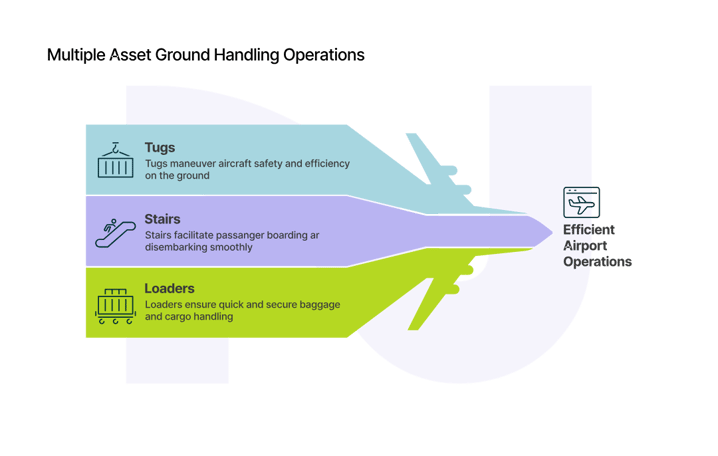

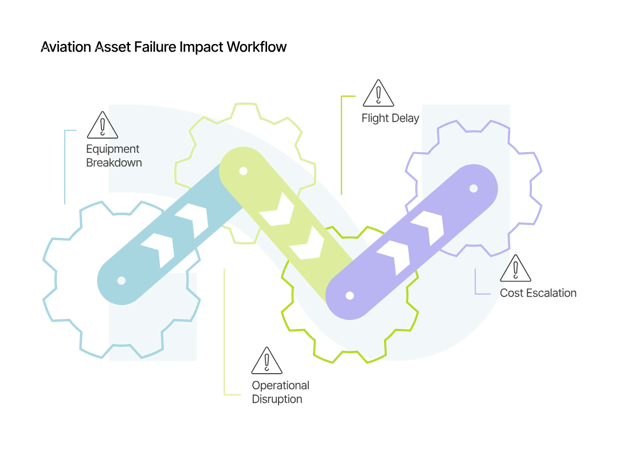

Aviation is one of the most asset-intensive industries in the world. Ground handling operations alone rely on fleets of tugs, belt loaders, passenger stairs, baggage systems, GPUs, and a wide range of specialised airport equipment. These assets are mission-critical: a single breakdown can delay flights, increase operating costs, and damage an operator’s reputation with airlines and passengers.

Yet many aviation service providers still manage these assets through fragmented systems, paper-based processes, and reactive maintenance models. This leads to:

-

Inconsistent SLA performance with airlines and airport authorities.

-

Delays in repairs due to poor inventory visibility.

-

Higher operational costs from unnecessary downtime.

-

Reduced compliance with aviation safety and operational standards.

Technical Diagnosis

The challenges in aviation asset management can be traced to several root causes:

-

No unified platform: Maintenance, inventory, and supplier data live in separate systems.

-

Reactive approach: Maintenance is performed only after breakdowns, impacting service continuity.

-

Limited inventory tracking: Spare parts are rarely available when needed, delaying repairs.

-

Compliance complexity: Aviation standards require detailed records and audit trails.

"In aviation, every minute counts. The right data at the right time is the difference between a smooth turnaround and a costly delay."

— Pedro Morais, CTO, Nextbitt

Solutions and Trade-offs

|

Solution |

Maintenance Model |

Compliance Tracking |

SLA Performance |

Cost Efficiency |

|

Manual spreadsheets |

Reactive |

Poor |

Inconsistent |

Low |

|

Legacy CMMS |

Preventive only |

Partial |

Moderate |

Medium |

|

Nextbitt EAM + Maintenance Suite |

Condition-based + Predictive |

Full |

High |

High |

Why Nextbitt for Aviation:

-

Centralises asset, maintenance, inventory, and supplier management.

-

Supports condition-based maintenance with IoT integration.

-

Tracks SLA performance with automated alerts and reporting.

-

Integrates with ERP, procurement, and airport operations systems.

-

Ensures compliance with aviation safety and operational standards.

Real-World Use Case

A major multi-airport operator uses Nextbitt across several airports to unify its operations.

Implementation Highlights:

-

Assets managed: 5,405

-

Maintenance orders processed:

-

Corrective: 79,505

-

Preventive: 31,466

-

-

Service requests handled: 53,584

-

Inventory: 21,705 items across 7 warehouses

-

Stock movements: 173,025 annually

-

Purchase orders: 80,969 per year

-

Preparations completed: 272

Key Outcomes:

-

Full digitalisation of asset and maintenance management.

-

Significant reduction in delays caused by equipment breakdowns.

-

Real-time inventory tracking prevents parts shortages.

-

Improved SLA compliance with airlines and authorities.

-

Better planning for resources and CAPEX investments.

Stats and Benchmarks

-

A single hour of aircraft or ground equipment downtime can cost airlines $10,000–$150,000, depending on aircraft size and delay length. Source: IATA – Guidance Document: Interline Considerations on Irregular Operations (IROPs), see p.5

-

Predictive maintenance can reduce aviation maintenance costs by 18–25% and unplanned downtime by up to 50%. Source: McKinsey & Company – Aircraft MRO 2.0: The digital revolution

Technical Evaluation Checklist

- Condition-based and predictive maintenance

- Integrated asset, inventory, and supplier management

- SLA tracking with automated escalation

- Compliance-ready audit trails for aviation safety standards

- Real-time dashboards accessible on mobile devices

- API integration with ERP and airport operations platforms

Product Integration and Use

Nextbitt’s modular platform allows operators to:

-

Centralise all airport asset data.

-

Integrate IoT for real-time monitoring.

-

Automate preventive and corrective maintenance workflows.

-

Optimise stock management and purchasing.

-

Generate compliance-ready reports for regulators.

Final Thoughts

In aviation, operational excellence is not optional — it underpins safety, passenger satisfaction, and profitability. With the growing complexity of airport ground operations, centralised asset and maintenance intelligence has become essential.

Digitalisation with Nextbitt demonstrates how operators can reduce downtime, strengthen compliance, and optimise resources — ensuring that from tarmac to terminal, every asset and every process is under control.

Technical FAQ

-

Can Nextbitt integrate with airport management systems?

Yes — it connects with operations databases, ERP, and procurement systems via open APIs. -

Does it support multi-site, multi-airport operations?

Absolutely — it is designed for complex structures, role-based access, and consolidated reporting. -

Is it compliant with aviation standards?

Yes — it provides full traceability and audit logs aligned with IATA, EASA, and local authority requirements.

.png?width=50&height=50&name=baixados%20(1).png)